Product

Solid Edge Simulation

Le logiciel est proposé en 3 variantes et nous vous proposons, pour en savoir plus, de visiter notre site web.

Price of the Product

Characteristics of the Product

- Type Logiciel de calcul de structure

- Model Solid Edge Simulation

- Brand Siemens

Category of the Product

Company website

Our recommended products and services

-

-

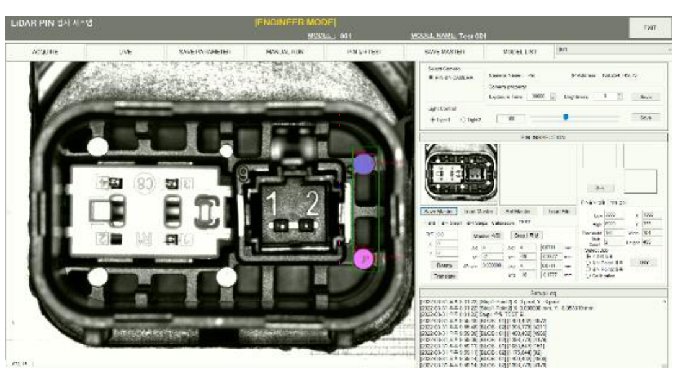

| Facility Management | : Smart Factory Solution By converging production facilities with IoT, big data, and artificial intelligence technology, we maintain productivity as an optimal partner through facility monitoring. [ Lidar Pin Inspection System ] - Automotive Parts PIN lns pection - PIN uprightness test [ AVT Vision System ] - Alignment inspection using - marker function [ Injection molding inspection system ] - Inspection of plastic injection molding results - Whether or not bolts are fastened, the state of product engraving

-

MWS have industry leading food processing and traceability software available to enable our clients to improve their business using latest technologies available. . We work closely clients to provide a full turnkey package and manage the project from start to finish ensuring full client satisfaction. Contact us today to enquire about our software solutions. OCM – Outer Case Marking System The Outer Case Marking System or OCM for short incorporates a Windows touchscreen terminal, an industrial label printer and weighing platform into a hygienic stainless steel frame that can be portable or fixed in one location. TraceWaste TraceWaste is our Waste Management software application, designed to identify prime waste generators and areas for improvement. Our software will help you to lower costs and improve profits. OCM Labelling Solutions WeighLogic Packing Management software is developed as a standalone or networked OCM solution that provide an unparalleled Outer Case Marking system for the UK food industry. WeighLogic Core Manufacturing companies rely on data collected from operations to monitor production efficiency. This data may be recorded on pen and paper and then input into a computer program, or the company may have extended their computer system to include data input terminals on the shop floor, enabling data to be captured automatically. MWS WeighLogic is what is known as a Manufacturing Execution System (MES). This is a computerised system used in manufacturing, to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision makers understand how current conditions on the plant floor can be optimised to improve production output. WeighLogic works in real time to enable the control of multiple elements of the production process. WeighLogic may operate across multiple function areas, for example: management of product definitions across the product lifecycle, resource scheduling, order execution and dispatch, production analysis, product quality, or materials track and trace. WeighLogic creates the “as-built” record, capturing the data, processes and outcomes of the manufacturing process. This can be especially important in regulated industries, such as food and beverage or pharmaceutical, where documentation and proof of processes, events and actions may be required. For more information contact us on 0845 260 2602 or visit our website: https://www.mws.ltd.uk

-

The LINK loadcell-to-USB is a small light box that connects directly to a USB connector on a PC – and a loadcell. No external power supply is required. The unit comes with the TramSmart software running on Microsoft Windows XP/Vista/Windows 7 Using the TramSmart software you can save identification (with calibration data) for several loadcells, and when starting the TramSmart software you select the connected loadcell from a list. The load is displayed on the PC and it can be transferred to any Windows program – just by using a shortcut key. Due to the extremely high accuracy, it is ideal for calibration purposes, but it is also very handy for all kinds of in-field measurements. You can save snapshot values or you can select continuous sampling – and the data will be put in the clipboard – ready for pasting into any program. The TSU – Sensor to USB: Is ideal for a full-bridge sensor, e.g. a loadcell, pressure sensor, or an extensometer. It can also be used for potentiometer, thermocouple, and other low voltage sensors. Is an easy way to record measurements of force, strain, position, temperature, etc. on a PC. Is ideal for both snapshot as well as continuous recording. Have an outstanding accuracy and a resolution with more than 1 million divisions. Is ideal for various laboratory and in-field measurements. Is the answer for all calibration purposes with force/pressure sensors and extensometer. Is small and light – only 470 g Simultaneous sampling of all channels Optional external trigger button in a 2m long wire Simple to use software will enable the operator to grow familiar with the LINK-sensor-to-USB after a very short time, even if he has no experience at all in operating a PC. The equipment offers a great opportunity to improve both laboratory and in-field measurements through instantaneous data generation. It is ideal for calibrating testing machines according to EN ISO 7500-1. With TramSmart for Microsoft Windows XP/Vista/Windows 7: Automatically detects LINK 4-loadcell-to-USB at startup of TramSmart On demand or continuous recording of measurements Various calibration methods and identification of any channel combination Simultaneously display of all channels and channel-combinations. Shortcut key to transfer measurements to any MS Windows program. Optional display of additional devices, e.g. Thickness Gauge, Extensometer, extra loadcells, balances, etc. Due to the modular design and the versatility of the software, tailored systems can be offered at a moderate price. Please contact TRAM or your local distributor for additional information.

-