Product

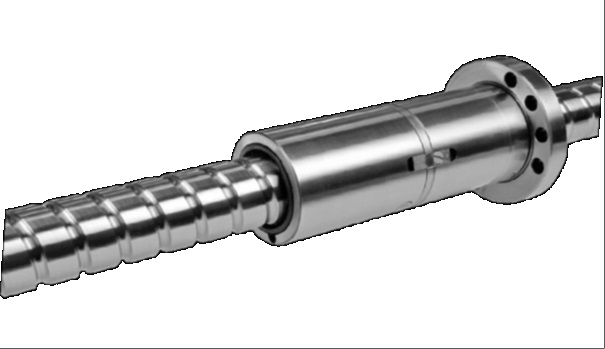

High-efficiency ball screws

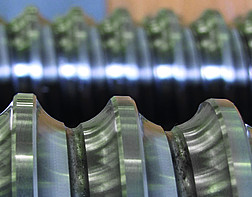

These ball screws are designed for applications requiring high efficiency of the transmission. They are used especially in machine tools and other equipment which meet the requirements for low energy consumption, as well as where high efficiency is required in order to eliminate heat sources or when an optimal ball screw drive is needed. The high efficiency is achieved by an accurate thread profile ground section, by precise geometry of the groove and alternatively by the use of ceramic balls in the recirculation system.

These ball screws are produced in the precision classes IT1 to IT5.

For this type of ball screws the following nut types are available:

- All types of nuts, non-preloaded nuts with backlash up to 0.05 mm

- Application of ceramic balls, special gothic thread profile

- Precise positioning ground ball screws

- Standard geometric and working accuracy according to DIN ISO 3408

- Reduced Tp values (usually by 15 to 20% against the standard)

- Diameters from 12 to 63 mm

- Recommended pitch up to 10 mm

- Precision classes from IT1 to IT5

- Do×n = 80.000, efficiency 96–98% (according to thread pitch and lubricant)

- Minimum strength of the shaft material Rm= 650MPa, functional surfaces of the shaft and nut hardened to 58–60HRC

- Working temperature -20 to +60°C

- A lubricant with reduced noise is recommended for a smooth run

- Energy saving machine tools

- Laboratory and measuring equipment

- Aerospace industry

These ball screws have no separate technical parameter table and they can be supplied with different nut units (A, AP, A+A, AP+A,

APR).

Example of designation: K63x10 – 4/AP HE/2 (ball screw with diameter 63 mm and pitch 10 mm, 4 working threads, single non-preloaded nut with flange, high efficiency design, flange type 2)

High-efficiency ball screws : www.ks-kurim.cz/en/ball-screws/high-efficiency-ball-screws/