Product

BAG FILTER DUST COLLECTION SYSTEM

The Development Of The Fabric Filter

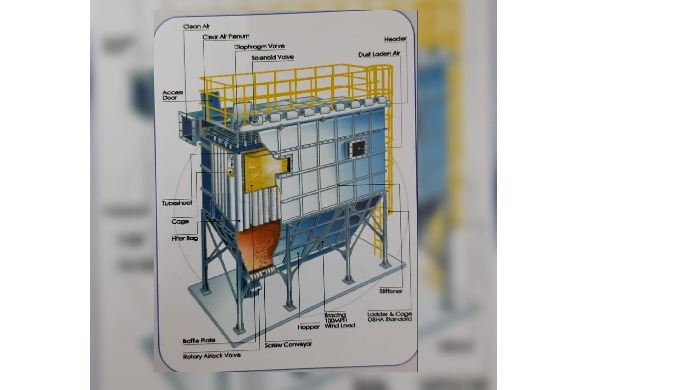

The pulse jet bag filter has been developed more recently and is now widely recognised as the most efficient type of fabric filter available. The dust laden air is introduced via an entry manifold at the top of the filter dust chamber or in the case of very high dust loadings into a seperate inlet aisle. Heavy particles will be deflected directly into the hopper while lighter particles are drawn onto the outside of the filter socks to form a dust cake.

Preiodic pulsing of the filter socks[row by row] dislodges the dust cake into the hopper and thus maintains fabric permeability at a level which allows continous operation. The pulse, a short burst of compressed and clean air induced by the sonic nozzle pulse causes a pressure wave to travel down the filter socks inflating the fabric and dislodging the dust.

The design of filter includes a high level entry which provides a downward movement in the dust chamber further assisting to deposit dust in the hopper and avoiding the common problem of loss of efficiency due to re entrainment.

Characteristics

- High efficiency filter bags selected for the specific application

- Heavy Duty all welded construction

- Special pressure gauge

- Access platforms and ladders

- Easily changeable bags